POWERMILL

Simplify CAM programming of large molds, tools, dies, and other complex 3D parts.

What is Autodesk Fusion 360 with PowerMill?

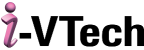

Autodesk PowerMill is expert CAM software for programming molds, dies and highly complex components requiring maximum quality, control, and efficiency of your CNC machines. Access a vast library of toolpath strategies and combine with advanced optimization tools to generate the NC code needed to produce exceptional quality parts. Use powerful simulation tools to validate and enhance the motion of 5-axis machines and industrial robots.

Why Powermill?

Maximize CNC machine utilization

Advanced controls help optimize NC code to extract maximum value from your machines and cutting tools.

Reduce CAM programming times

Super-fast toolpath calculation makes it simple to program large molds, tools and dies, and other challenging 3D geometry.

Deliver exceptional part quality

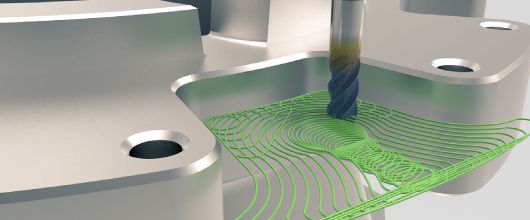

Complete control of the machining process helps you achieve optimum levels of precision and surface finish.

What you can do with Autodesk Fusion 360 with PowerMill

Solve complex CNC machining problems

PowerMill provides a vast library of 3- and 5-axis strategies that simplify the CAM programming and CNC machining of large molds, tools, dies and other complex parts. (video: 1:33 min.)

Achieve exceptional levels of quality

Advanced toolpath controls and powerful editing shortens CAM programming times and increases flexibility, resulting in finished parts that require little to no manual polishing. (video: 3:01 min.)

Improve consistency with automation

Powerful templates and user-defined macros help you capture and share best practices across your team. Address the skills gap and help your workers to be more productive sooner.

Which Powermill version is suitable for you?

Fusion 360 with PowerMill Standard

Rapidly create NC code for high-speed 3-axis machining, 3+2 programming, 2.5D milling, and turning, plus machine simulation and toolpath verification.

Fusion 360 with PowerMill Ultimate

Access full 5-axis programming with automatic collision avoidance, machine simulation, robot programming, automated electrodes, hybrid manufacturing, and more.